ViewMold Co Ltd is an ISO 9001:2000 certified plastic injection molds company that supplies

plastic injection molds

plastic injection molds design

plastic injection molds manufacturing of high quality,plastic injection molding...

We are Proud to bring to you the quality and speed you would expect from Viewmold plastic injection molds. We believe we will be your supplier of choice. Just give Viewmold a

email or

submit a quote online.

Our team of quote specialists is the most responsive and the most hands on.

BOSTON?/span> IS YOUR BEST SOURCE . . .

MITER AND BEVEL GEARS

90?Intersecting Shaft Applications

Coniflex Tooth Form for Increased Life and

Smoother, Quieter Operation

Spiral Miter and Bevel for Higher Speed, Greater

Torque Load, and Quieter Operating Applications

Miter Gears for 1:1 Ratio Applications

Bevel Gears for 1.5:1 to 6:1 Ratio Applications

Soft Bores for Customized Alterations

Selections from Stock

Straight Miter Gears

CNylon (48 DP -16 DP)

CBrass (48 DP -24 Dp)

CSteel (48 DP -4 DP)

CIron (8 DP -4 DP)

Spiral Miter Gears (35?Spiral Angle)

CSteel (18 DP -5 DP)

Straight Bevel Gears

CBrass (48 DP -24 DP)

Steel (20 DP -6 DP)

CIron (16 DP -4 DP)

Spiral Bevel Gears (35?Spiral Angle)

CSteel (30 DP -8 DP)

Diametral Pitch -48 DP to 4 DP)

Pitch Diameter -0.250" to 9.000

20?Pressure Angle

Hardened or Unhardened Teeth (Steel)

Made in Accordance with AGMA

Specifications for the Basic Tooth Form

Boston miter and bevel gears are designed for transmission of motion and

power between intersecting shafts positioned at a right angle. Straight tooth

miter and bevel gears are cut with a generated tooth form having a localized

lengthwise tooth bearings known as the ?Coniflex tooth form. The superiority

of these gears over straight bevels with full length tooth bearing lies in the control of tooth contact. The localization of contact permits minor adjustment of

the gears in assembly and allows for some displacement due to deflection

under operating loads, without concentration of the load on the end of the

tooth. This results in increased life and quieter operation.

Spiral tooth form miter and bevel gears are suited for higher speed and larger

torque applications.

Boston stock miter and bevel gears are designed for transmission of power

and/or motion between intersecting shafts at a right angle (90?). Miter gears ar

a special type of bevel gear designed to operate as pairs being identical in number of teeth and pitch (1 to 1 ratio only). Other Boston stock bevel gear sets are available with ratios from 1-1/2:1 to 6:1.

All Boston standard stock bevels and miters are manufactured with a 20?pressure angle. These bevel gears are made in accordance with AGMA specifications for a long and short addendum system for gears and pinions, which serves

to reduce the amount of pinion tooth undercut and to nearly equalize the strength

and durability of the gear and pinion. Boston straight tooth bevel and miter gears have generated teeth with ?Coniflex

tooth form, unless otherwise specified.

INTERCHANGE

Stock miter and bevel gears having identical diametral pitch, number of teeth

and mounting distance (and spiral angle for spiral bevels) are interchangeable.

SPIRAL VS. STRAIGHT TOOTH

Boston standard stock straight bevel gears can be used for all applications

requiring transmission of power and motion between intersecting shafts. Boston

standard stock spiral bevel gears have an overlapping tooth action which results

in a smoother gear action, lower noise, and higher load capacity than a straight

bevel of equal size.

SELECTION PROCEDURE

Approximate horsepower ratings for selected sizes (number of

teeth) at various operating speeds (RPM) are given for Boston

standard stock Bevel and Miter gears.

For straight tooth Miter gears, refer to Pages 68, 69.

For straight tooth Bevel gears, refer to Page 70.

For spiral tooth Miter gears, refer to Page 71.

For spiral tooth Bevel gears, refer to Page 71.

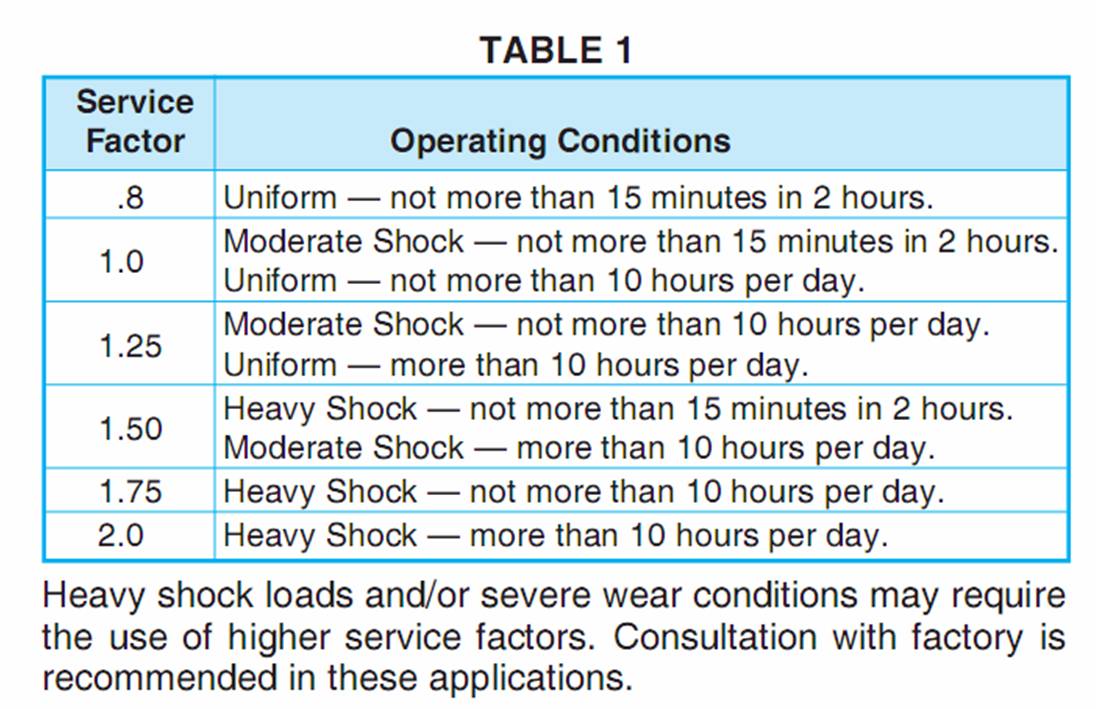

All ratings are based on normal operating conditions, that is:

properly mounted and lubricated, carrying a smooth load for

not more than 10 hours (Service Factor = 1.0). Refer toTable 1

for service factors in other service conditions.

1. Determine service factor.

a.Using Application Classification Chart I, pages 152(R)C15 determine service factor or

b.With knowledge of operating conditions and load classification, select service factor from Table 1.

2. Determine Design Horsepower.

Design HP = Application Load x Service Factor (Table 1)

3.Select a gear set with horsepower capacity equal to (or

greater than) design horsepower determined in Step 2.